HAVER & BOECKER oHG – BEHN + BATES - YOUR PARTNER FOR PACKAGING SOLUTIONS FOR THE FOOD INDUSTRY

Consider everything okay!

Are you ready to create packaging for your products reliably and efficiently? Then enter into a successful partnership with BEHN + BATES – a brand of HAVER & BOECKER!

As a specialist in technology and service maintenance for high-quality packaging machines, we offer comprehensive support - from the supply of equipment to the development of process technologies and digital solutions, diagnostics for the optimization and modification of equipment, as well as the management of spare parts and maintenance support. In addition, we develop and supply packaging materials.

Our equipment

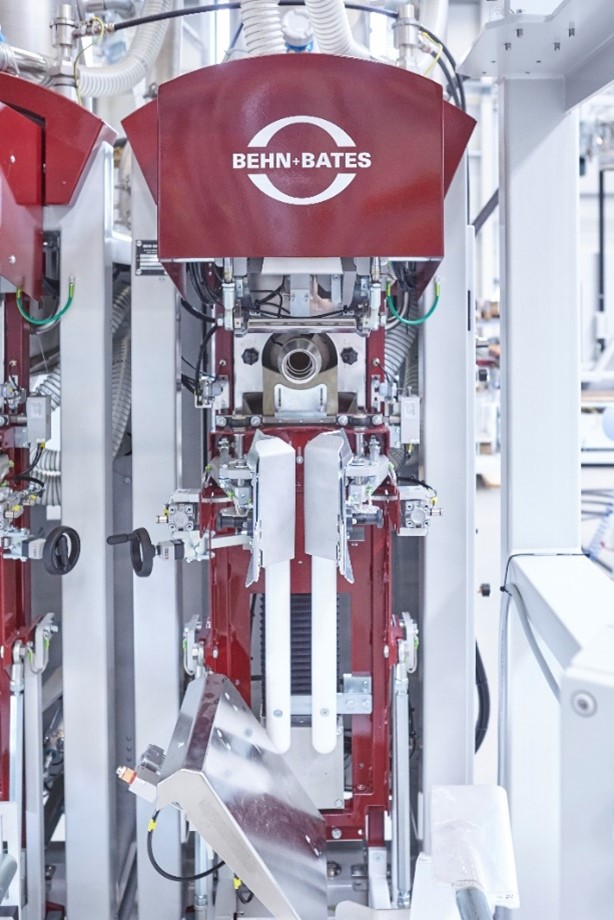

Our ELEMENTRA®

Trust our simple solutions for your filling process.

The history of valve bag technology begins with a stationary filling machine. The innovative ELEMENTRA® stationary filling machine is highly valued by our customers worldwide for its intelligence, cost-effectiveness and cleanliness. And it has been this way for decades.

For filling, the bag is placed on the filling nozzle manually or automatically. The product is fed using a special filling technology (air or turbine) developed for your product. Depending on the type of machine, the filled bag is either removed from the nozzle manually or dropped automatically.

Our INTEGRA®

Integrate the benefits of our INTEGRA FD® into your filling process.

Low noise of machine, clean working environment: from bag feeding, filling and sealing of bags takes place in a dust-proof sealed cabin. Our Plug'n Pack concept also ensures quick machine setup in your production.

INTEGRA FD® is available in a design with 1 to 4 filling modules for flexible production planning. Depending on your product, it is equipped with a suitable product feed system – air or turbine.

Our ROTO-PACKER®

Increase your filling line productivity with our ROTO-PACKER®

With our ROTO-PACKER® for valve bags, a maximum capacity of 2,400 bags per hour can be achieved. The ROTO-PACKER® filling modules are mounted on a rotating frame. This saves space for installing the filling machine. The bags can be fed to the filling nozzles either manually or automatically with our automatic RADIMAT® bag placing unit. Before dropping, the bag valve can be sealed directly at the filling nozzle with our ultrasonic valve sealing device.

Our ROTO-PACKER® works with the appropriate feed system for your product – air or turbine. You decide how many filling modules your ROTO-PACKER® will have: is the performance or the possibility of future expansion is important?